Sand screen is a commonly used solution to control sand production in wellbores.

Sand Screen is an integral part of most downhole sand control systems. Acting as a filter, it allows reservoir fluid ingress to the completion string while keeping the sand out.

Why we need a sand screen?

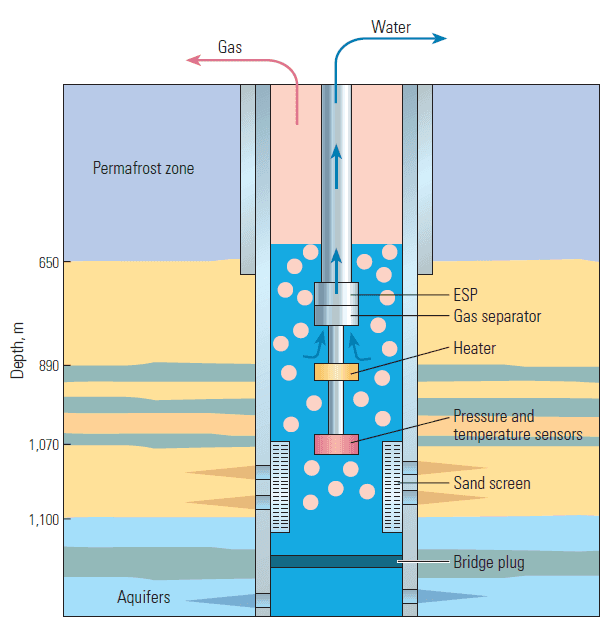

Oil and gas reservoirs exist in all types of sands. Besides, wells drilled through unconsolidated rock formations that may collapse into the wellbore. Sand production in wellbores can lead to production impairment due to sand plugging, erosion to completion string and downhole tools and damage surface facilities, etc. Sand screens inserted into the wellbore can enhance wellbore stability, block sand out and optimize productivity when run in unconsolidated formations. Therefore, sand screens are highly recommended in producing oil, natural gas and water.

Sand screen is a commonly used solution to control sand production in wellbores.

Application

Sand screen is a commonly used method to control, mitigate and prevent sand production in wellbores and extend the service life of wellbores. It is highly recommended in the following situations:

Sand screen is widely applied in oil or water wells.

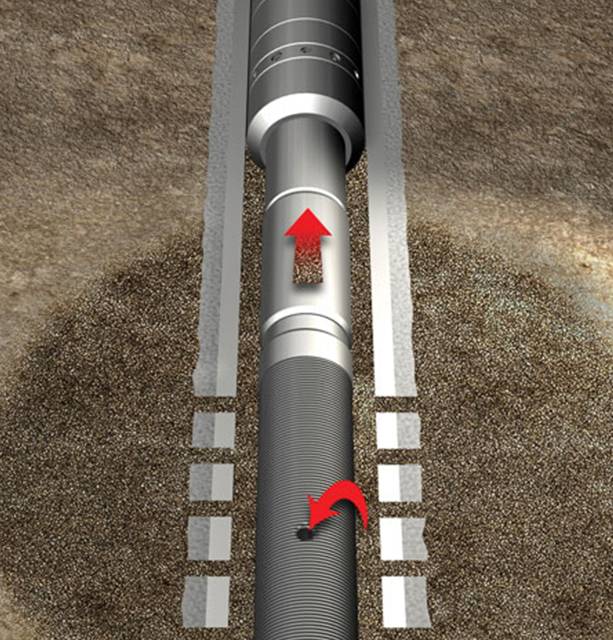

Sand screen installation location

Wire wrapped screen is one of the most commonly used sand screens around the world. It consists of a base pipe and a filter jacket or only a filter jacket. It adopts world advanced all-weld technology to ensure that wrap wire welded to ribs at every contact point, which provides a robust solid filter for use in both cased and openhole environments. It creates a continuous slot opening and allows water or oil entering well freely in ample quantifies while keeping most of the sand and gravel out of the well.

Structure

Wire wrapped screen has excellent corrosion resistance and superior erosion resistance.

Details

The cross section of the wire wrapped screen

Wire wrapped screen diagram

Advantages

Specification

Wire wrapped screen thread connection

Wire wrapped screen flange connection

Wire wrapped screen baffle ring connection

| Base Pipe OD in. (mm) | Base Pipe Holes per Foot | Base Pipe Hole Size in. (mm) | Open Area of Base Pipe Holes in.2/ft (cm2/m) | Number of Ribs | Filter Jacket | Screen Radial Open Area in.2/ft (cm2/m) | |

|---|---|---|---|---|---|---|---|

| Maximum Assembly OD in. (mm) | Jacket Weight lb/ft (kg/m) | ||||||

| 2.38 (60.45) | 54 | 0.375 (9.530) | 5.96 (126.20) | 15 | 2.86 (72.60) | 2.30 (3.42) | 12.60 (267.01) |

| 2.88 (73.15) | 66 | 0.375 (9.530) | 7.29 (154.30) | 17 | 3.36 (85.30) | 2.70 (4.02) | 14.80 (313.70) |

| 3.50 (88.90) | 78 | 0.375 (9.530) | 8.61 (182.20) | 21 | 3.99 (101.30) | 3.20 (4.76) | 17.60 (372.51) |

| 4.00 (101.60) | 90 | 0.375 (9.530) | 9.94 (210.40) | 23 | 4.49 (114.00) | 3.60 (5.36) | 19.80 (419.19) |

| 4.50 (114.30) | 102 | 0.375 (9.530) | 11.27 (238.50) | 25 | 5.00 (127.00) | 4.00 (5.95) | 22.10 (466.81) |

| 5.00 (127.00) | 114 | 0.375 (9.530) | 12.59 (266.50) | 27 | 5.51 (139.90) | 4.40 (6.55) | 24.30 (514.42) |

| 5.50 (139.70) | 126 | 0.375 (9.530) | 13.92 (294.60) | 29 | 6.01 (152.70) | 4.80 (7.14) | 26.50 (561.10) |

| 6.63 (168.40) | 138 | 0.375 (9.530) | 15.24 (322.60) | 31 | 7.15 (181.60) | 5.60 (8.33) | 31.50 (667.54) |

| 7.00 (177.80) | 150 | 0.375 (9.530) | 16.57 (350.70) | 37 | 7.53 (191.30) | 6.10 (9.08) | 33.20 (703.01) |

Technical Notes:

|

|||||||

Precise Micropore Composite Screen is designed to filter a high percentage of sands and is used in high velocity wells. It adopts an all metal design with a base pipe, a filter jacket and an outer protective shroud to provide better performance than a wire wrapped screen in unconsolidated formations. It is especially true when it comes to filtering fine particles in formations with more poorly sorted sands. The unique construction of this screen optimizes inflow area and filtration efficiency to provide superior sand control completion performance.

Precise micropore composite screen optimizes inflow area and filtration efficiency to provide better sand control performance.

Precise micropore composite is an ideal choice for wellbores in unconsolidated formations.

Precise micropore composite screen has high accuracy and reliability in sand control.

Structure

Details

The bridge-style pipe precise micropore composite screen

The perforated pipe precise micropore composite screen

Advantages

Specification

| Base Pipe OD in. (mm) | Base Pipe Holes per Foot | Base Pipe Hole Size in. (mm) | Open Area of Base Pipe Holes in.2/ft (cm2/m) | Filter Jacket | Screen Radial Open Area in.2/ft (cm2/m) | |

|---|---|---|---|---|---|---|

| Maximum Assembly OD in. (mm) | Jacket Weight lb/ft (kg/m) | |||||

| 1.05 (26.67) | 54 | 5/16 (7.94) | 4.10 (86.80) | 1.69 (42.93) | 1.20 (1.79) | 14.70 (310.17) |

| 1.32 (33.53) | 66 | 5/16 (7.94) | 5.10 (107.87) | 1.95 (49.53) | 1.40 (2.08) | 16.90 (357.89) |

| 1.66 (42.16) | 78 | 5/16 (7.94) | 6.00 (127.02) | 2.30 (58.42) | 1.70 (2.53) | 19.90 (422.12) |

| 1.90 (48.26) | 42 | 3/8 (9.53) | 4.60 (97.38) | 2.47 (62.74) | 1.90 (2.83) | 21.40 (453.32) |

| 2.06 (52.32) | 42 | 3/8 (9.53) | 4.60 (97.38) | 2.72 (69.09) | 2.20 (3.27) | 23.60 (499.21) |

| 2.38 (60.45) | 54 | 3/8 (9.53) | 6.00 (127.02) | 3.03 (76.96) | 2.50 (3.72) | 26.30 (556.10) |

| 2.88 (73.15) | 66 | 3/8 (9.53) | 7.30 (154.54) | 3.53 (89.66) | 3.00 (4.46) | 30.60 (647.87) |

| 3.50 (88.90) | 78 | 3/8 (9.53) | 8.60 (182.06) | 4.15 (105.41) | 3.40 (5.06) | 36.00 (761.66) |

| 4.00 (101.60) | 90 | 3/8 (9.53) | 9.90 (209.58) | 4.65 (118.11) | 3.80 (5.66) | 40.30 (853.42) |

| 4.50 (114.30) | 102 | 3/8 (9.53) | 11.30 (239.22) | 5.14 (130.56) | 4.30 (6.40) | 44.60 (943.35) |

| 5.00 (127.00) | 114 | 3/8 (9.53) | 12.60 (266.74) | 5.65 (143.51) | 4.60 (6.85) | 49.00 (1036.95) |

| 5.50 (139.70) | 126 | 3/8 (9.53) | 13.90 (294.26) | 6.16 (156.46) | 5.10 (7.59) | 53.40 (1130.56) |

| 6.63 (168.40) | 138 | 3/8 (9.53) | 15.30 (323.90) | 7.31 (185.67) | 6.00 (8.93) | 63.40 (1341.62) |

| 7.00 (177.80) | 150 | 3/8 (9.53) | 16.60 (351.42) | 7.69 (195.33) | 6.30 (9.38) | 66.70 (1411.36) |

| 7.63 (193.80) | 162 | 3/8 (9.53) | 17.90 (378.94) | 8.33 (211.58) | 6.90 (10.27) | 72.20 (1528.82) |

| 8.63 (219.20) | 186 | 3/8 (9.53) | 20.50 (433.99) | 9.35 (237.49) | 7.80 (11.61) | 81.10 (1716.02) |

| 9.63 (244.60) | 210 | 3/8 (9.53) | 23.20 (491.14) | 10.37 (263.40) | 8.70 (12.95) | 89.90 (1903.23) |

Technical Notes:

|

||||||

Bridge Slotted Screen is a kind of well filter pipe with bridge holes. It is an economical alternative to other types of sand screens. It has high mechanical strength, a variety of connection styles and easy operation performance. It is an ideal filter for water well drilling. It may work with a perforated pipe to enhance its mechanical strength. In addition, it can also be covered with an anti-corrosive coating to extend its service life.

Bridge slotted screen is an ideal filter for water well drilling.

Details

The structure of the bridge slotted screen

Detail of the bridge slotted screen

Specification

Bridge slotted screen of spiral seam welding>

Bridge slotted screen of straight seam welding

Bridge slotted screen thread connection

Bridge slotted screen flange connection

Bridge slotted screen welding connection

Advantages